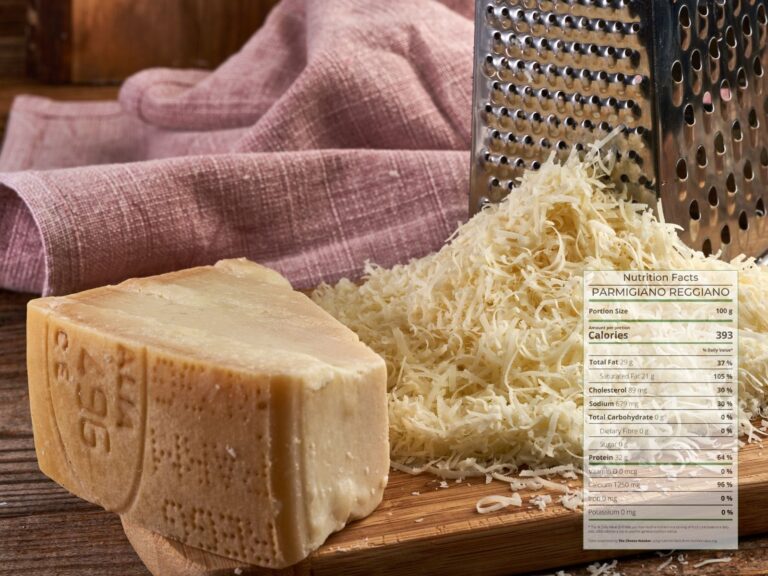

Parmigiano Reggiano is, undoubtedly, the king of Italian cheeses. And the traditional recipe used to make this iconic hard cheese has been passed on from one generation of cheesemakers to another in the area of production in northern Italy. Read this article to learn how Parmigiano Reggiano is made.

SEE ALSO: Why Parmigiano Reggiano is the King of Italian cheeses →

The area of production

Parmigiano Reggiano is produced exclusively in the provinces of Parma, Reggio Emilia and Modena. Furthermore, the authorised regions also include Bologna, to the left of the Reno River. And Mantua, to the right of the Po River.

Significantly, this area hosts numerous farms where farmers exclusively feed their cows locally grown grass and forage. Furthermore, the PDO prohibits the use of silage, fermented feeds and animal flour.

The art of making Parmigiano Reggiano

Unsurprisingly, it all starts with the raw milk. The cheesemaker mixes milk from the morning and the previous evening and pours the mixture into traditional upturned bell-shaped copper vats. Remarkably, it takes about 550 litres of milk to produce one wheel of Parmigiano Reggiano.

To the milk, the maker adds rennet and a whey starter which is rich in starter cultures from the previous day’s processing. As a result, the milk coagulates and starts to form curds.

Cutting the curd with a spino

Next, the cheesemaker uses a traditional tool called Spino to break down the curd into tiny grains. The curd is now ready to be cooked at 55°C (130°F). After this, the curd grains sink to the bottom of the cauldron to form a single mass.

About 50 minutes later, two cheesemakers work together to remove the cheese mass using a metal rod and cloth. Each one of those cheese masses will then be cut in half to produce two wheels of Parmigiano Reggiano. Finally, the maker wraps each wheel in a linen cloth and places it in a mould to give the cheese its final shape.

The final production steps

Once the cheese is formed, the maker applies a unique casein plate to each wheel. From this point onwards, this will be its identity card and can be traced back to its production site.

A few days later, they immerse the wheels in a saturated brine solution. Indeed, this marks the final step of the production process.

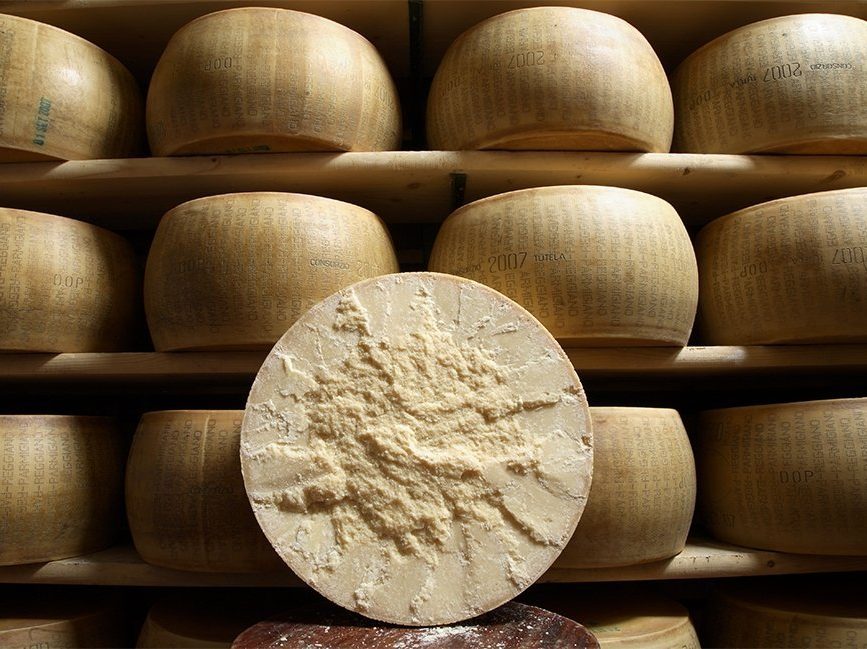

Off to the maturation rooms

Once the production steps are complete, the young wheel of Parmigiano Reggiano is ready for maturation. And the story of this maturation is a long, slow one, following the natural rhythm of the seasons in northern Italy.

But, as they say, this is a story for another day.