Cheddar is the world’s most popular cheese. But did you know that not all Cheddars are created equal? Read on to learn about how traditional Cheddar is made. And what cheddaring is.

SEE ALSO: Why Cheddar is the world’s most popular cheese →

Setting the curd

When making Cheddar, the cheesemaker first adds rennet to coagulate the fresh milk. Once the curd has set, they cut it into 6 to 16 mm (1⁄4 to 5⁄8 in) cubes using stainless steel wire knives.

Subsequently, they cook the curd by adding hot water (up to 39°C or 102°F). During this process, they stir the curd constantly to facilitate even cooking.

Overall, this step takes between 20 and 60 minutes. At the end, the pH of the whey (liquid) should be between 6.1 and 6.4 (slightly acidic).

Chemistry 101 – What is pH?

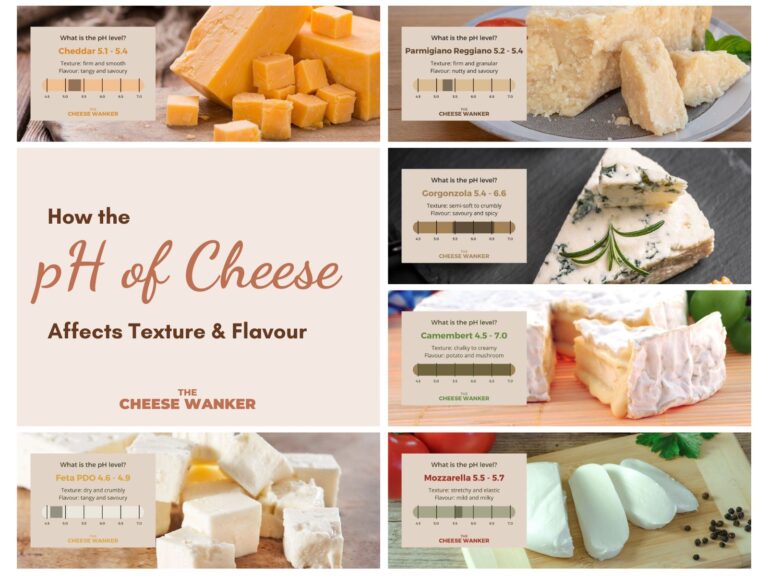

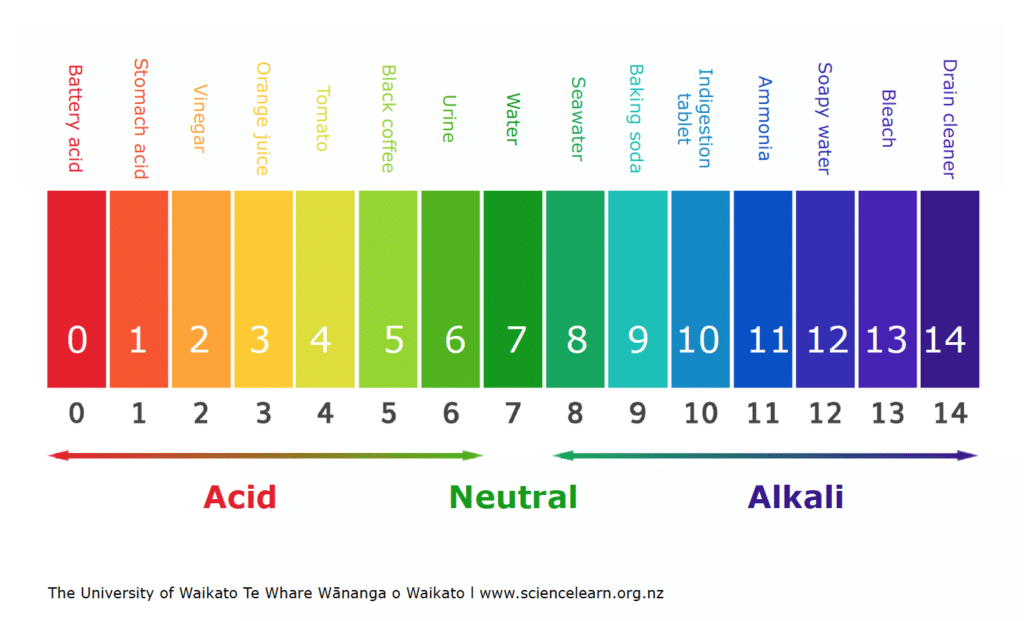

Quick chemistry 101 detour, pH is a measure of how acidic a solution is. A pH of 7 is smack down the middle and called neutral.

An example of a solution with neutral pH is water. Anything from 0-7 is referred to as acidic, and anything between 7 and 14 is called basic or alkaline.

The next step involves removing whey from the curds by allowing it to drain. Once the whey is gone, the curds are moved to the side of the vat.

What is Cheddaring?

Next comes the unique process that makes this cheese what it is, cheddaring. Effectively, this step involves stacking loaves of curd on top of one another in order to squeeze additional whey out of the loaves below.

“Loaves” of curds are cut about 15 cm(6 in) wide along each side of the vat. After ten minutes, the loaves are turned over and stacking begins.

Overall, this step is repeated several times with the cheesemaker turning over the loaves each time to evenly draw out the whey. Consequently, the curd becomes denser and even crumbly.

Milling and moulding

When the turning process is complete, the maker cuts down the loaves into a size that fits in the mill. The mill then cuts the curd into 1.3 cm (1⁄2 in) pieces.

Finally, salt is added and the curd is transferred into moulds that will press the curd and form the truckles of cheese. They are now ready for ageing.

The traditional way

Did you enjoy reading about how traditional Cheddar is made? Are there more cheeses that you would like to learn about? Drop us a comment below.